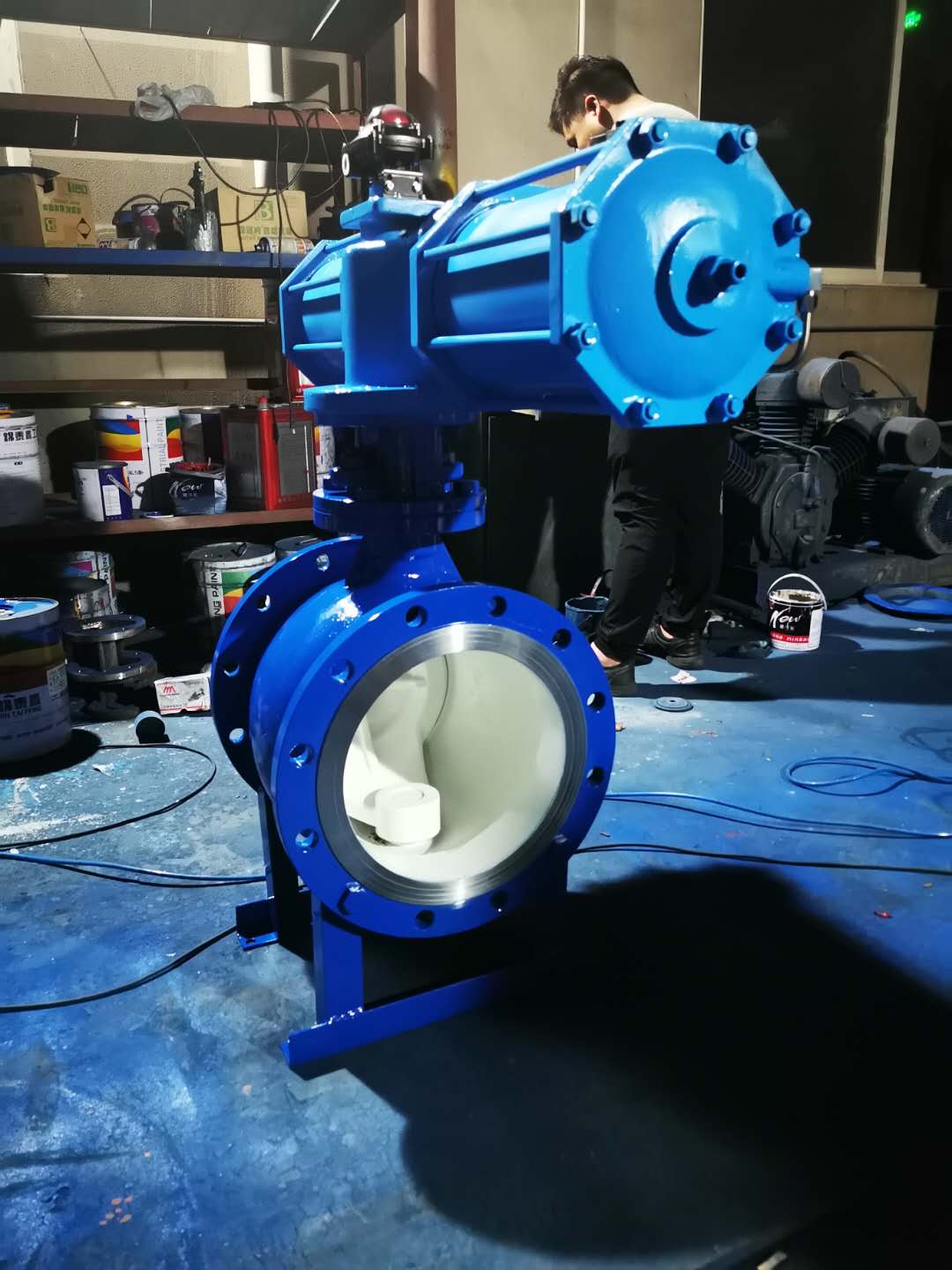

DN200 Double Acting Pneumatic Cylinder Segment Ball Valve

Application:

Two-part and three-part fixed ball valves are also called test-fit split ball valves. The valve body is divided into asymmetrical left and right halves along a section perpendicular to the axis of the valve channel. It is mainly used for cutting off, distributing and changing the pipeline. The flow direction of the medium. Its pivot structure ensures accurate ball position. The standard valve seat adopts a spring structure to push the valve cover to the sphere, ensuring a good low-pressure sealing performance. The valve seat of the ball valve can be sealed before and after the valve, that is, the so-called two-way sealing feature. Using the built-in discharge valve, the cavity of the valve body can be discharged outward. The pivot adopts an anti-blowout protection structure, bearings with low friction coefficient, etc. It has the advantages of excellent performance, high reliability, wide range of uses, and reasonable price.

Electric fixed ball valve is suitable for chemical, petroleum, natural gas, metallurgy, and other industries and long-distance natural gas pipelines containing hydrogen sulfide media, many impurities, and serious corrosion.

Features:

Q347F flanged fixed ball valve, also known as test-mounted split ball valve, divides the valve body into asymmetrical left and right halves along the section perpendicular to the axis of the valve channel. It is mainly used to cut off, distribute and change the direction of medium flow in the pipeline. . Its pivot structure ensures accurate ball position

Technical Standard:

| Test Pressure(Mpa) | Norminal Pressure(Mpa) | Pressure Class(Class) | JIS(MPa) | |||||||||

| 1.6 | 2.5 | 4.0 | 6.4 | 10.0 | 150 | 300 | 400 | 600 | 900 | 10K | 20K | |

Strength Test | 2.4 | 3.8 | 6.0 | 9.6 | 15.0 | 3.1 | 7.8 | 10.2 | 15.3 | 23.1 | 2.4 | 3.8 |

| Sealing Test | 1.8 | 2.8 | 4.4 | 7.0 | 11.0 | 2.2 | 5.6 | 7.5 | 11.2 | 16.8 | 1.5 | 2.8 |

| Airtight Test | 0.5-0.7 | |||||||||||

| Working Temperature | PTEE≤150℃ PPL E≤300℃ Carbon fiber≤350℃ | |||||||||||

| Medium | C: water, oil, steam P: nitric acid (temperature ≤200℃) R: acetic acid (temperature ≤200℃) | |||||||||||

Material of main parts of electric fixed ball valve:

Part Name | Material | |||

Material Code | C | L | P | R |

Body Bonnet | WCB | ZGOOCr17Ni14Mo2(CF3M) | ZG1Cr18Ni9Ti(CF8) | ZG1Cr18Ni12Mo2Ti(CF8M) |

Sphere | 2Cr13 | ZGOOCr17Ni14Mo2(CF3M) | ZG1Cr18Ni9Ti(CF8) | ZG1Cr18Ni12Mo2Ti(CF8M) |

Stem | 2Cr13 | 316L | 1Cr18Ni9Ti(304) | 1Cr18Ni12Mo2Ti(316) |

Seat Sealing Surface | PTFE, carbon fiber + PTFE, para-polystyrene | |||

Stud and Nut | 35 35CrMoA(B7) 45(2H) | 2Cr13(420) 1Cr18Ni9 1Cr17Ni2(431) | ||

Filler | V-shaped PTFE, flexible graphite | |||

Main Diameter and Dimensions:

| Norminal Pressure(MPa) | Norminal Diameter | L | D | D1 | D2 | D6 | b | f/f1 | z-φd | H(mm) | Weight(kg) | ||||||||||

| mm | mm | Q47 | Q347 | Q647 | Q947 | Q47 | Q347 | Q647 | Q947 | Q67 | Q367 | Q667 | Q967 | ||||||||

| 1.6 | 100 | 229 | 215 | 180 | 155 | - | 20 | 8-18 | 178 | 416 | 470 | 45 | 78 | 85 | 40 | 73 | 80 | ||||

| 125 | 356 | 245 | 210 | 185 | - | 22 | 8-18 | 152 | 542 | 520 | 58 | 107 | 120 | 50 | 100 | 110 | |||||

| 150 | 394 | 280 | 240 | 210 | - | 24 | 8-23 | 205 | 572 | 538 | 117 | 145 | 180 | 100 | 130 | 160 | |||||

| 200 | 457 | 335 | 295 | 265 | - | 26 | 12-23 | 398 | 736 | 580 | 185 | 220 | 245 | 155 | 200 | 220 | |||||

| 250 | 533 | 405 | 355 | 320 | - | 30 | 12-25 | 495 | 890 | 637 | 245 | 280 | 300 | 215 | 255 | 280 | |||||

| 300 | 610 | 460 | 410 | 375 | - | 30 | 12-25 | 580 | 910 | 683 | 395 | 450 | 445 | 345 | 415 | 400 | |||||

| 350 | 686 | 520 | 470 | 435 | - | 34 | 16-25 | 625 | 1020 | 796 | 516 | 570 | 585 | 500 | 520 | 540 | |||||

| 400 | 762 | 580 | 525 | 485 | - | 36 | 16-30 | 720 | 1080 | 842 | 756 | 920 | 860 | 700 | 920 | 805 | |||||

| 450 | 864 | 640 | 585 | 545 | - | 40 | 20-30 | 770 | 1120 | 874 | 958 | 1140 | 1075 | 900 | 1140 | 1010 | |||||

| 500 | 914 | 705 | 650 | 608 | - | 44 | 20-34 | 840 | 1150 | 904 | 1200 | 1360 | 1310 | 1100 | 1360 | 1240 | |||||

| 600 | 1067 | 840 | 770 | 718 | - | 48 | 20-41 | 1050 | 1210 | 1120 | 1500 | 1620 | 1450 | 1400 | 1620 | 1360 | |||||

| 700 | 1245 | 910 | 840 | 788 | - | 50 | 24-41 | 1100 | 1300 | 1218 | 1800 | 1930 | 1810 | 1680 | 1930 | 1710 | |||||

| 800 | 1397 | - | - | - | - | - | - | 1150 | 1460 | 1328 | 2100 | 2250 | 2010 | 1980 | 2250 | 1910 | |||||

Related Valves:

Tel:+86-023-40514869

Fax :+86-023-40514869

Mobile:+86-13648311944

Email: sales@jinfa-industrial.com

Skype: chenkaiwen36

Whatsapp: +86-13648311944